Plastic Injection; It is a process that involves melting a plastic raw material, then injecting it into the mold and removing it after cooling. In order to remove the plastic raw material from the mold, it needs to cool.

Plastic injection with the process; Many plastic parts such as garden furniture and components can be produced. Plastic injection is widely used in industrial areas in general. We can say that this method plays an active role in the production of many of the items we see around us. It has become a very preferred method especially because it is suitable for mass production.

Plastic Injection the mold process has a unique working principle. We can list this working principle as follows;

Plastic Injection It is an advantageous application. We can list the advantages of plastic injection as follows;

Plastic Injection it is a very easy process. It is preferred because it does not have a complex structure.

Plastic Injection process steps are as follows:

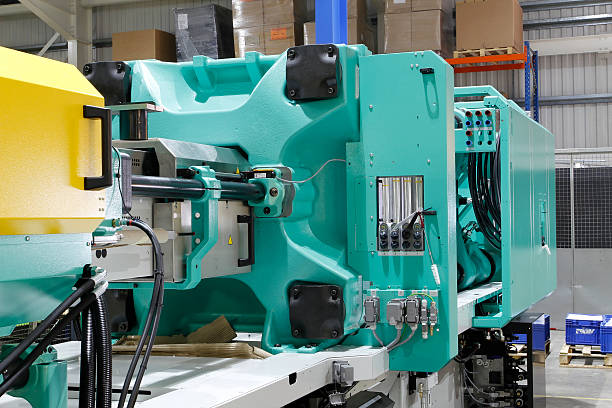

In the mold closing unit of the plastic injection machine, the mold is kept under pressure during the injection cooling processes.

It is the process stage that expresses the melting of the plastic raw material into the mold.

It is the process step that expresses the transfer of the molten plastic material into the mold through the nozzle at the end of the machine. The raw material sent to the mold cavity is compressed in the mold by the effect of the pressure. Then the raw material begins to cool.

It is the stage applied in order for the product to be in the desired dimensions. The plastic plum injected into the mold fills the entire mold cavity with pressure. This process ends when the plastic becomes solid in the mold.

The mold is cooled and frozen in the plastic inside.

Plastic Injection It is the penultimate before the process stages of the process. It is the removal of molded plastic material from the mold.

With the help of the pushers, the molded part is removed from the mold.

Plastic Injection must be done by professionals. Umaymak firm performs plastic injection process with its professional teams.